On The Front Foot

Two friends join forces to disrupt and rejuvenate Britain’s luxury shoemaking industry.

It started, as so many successful businesses do, with two friends trying to solve a problem. After meeting on their first day at the University of Kent, Jahangir Azam, known to his friends as Jay, and Christopher Boadle, followed separate career paths; Boadle into ed-tech and Azam into banking, until a chance meeting in London brought them together in 2013 as future co-founders of a bespoke and sustainable shoe company.

A talking point was Azam’s futile search for a pair of new shoes. He was attending a friend’s wedding in Panarea, a party island in Sicily, and wanted something unique. “It was proving impossible and after continuing to complain to me about it, one morning we decided to jump in the car and go on a treasure hunt for a shoemaker,” recalls Boadle.

“When we did finally track someone down, Jay's pair were made from black velvet with embroidered lightning bolts on the front. I commissioned a pair shortly afterwards, choosing emerald-green velvet and, upping the ante, I designed a pair of Aztec-inspired eagles, embroidered in gold. They were the life of the party,” says Boadle.

When a close school friend passed away, Boadle decided to readdress his priorities and took a sabbatical, yearning for something more tangible than technology. Azam was also at a point where he was seeking a meaningful shift in his professional journey, driven by a desire to create something enduring and impactful. This shared aspiration, fuelled by their reunion, became the catalyst for a venture that would not only redefine their careers but also leave an indelible mark on the world of sustainable fashion.

With a family background in luxury fashion and textiles, Azam had a good starting point. The two joined forces and started designing and making shoes for friends and friends of friends. They started the business on a kitchen table. The name 'Arthur Sleep' was chosen for its playful character, reflecting the brand's lighthearted spirit. "We aimed to personify the brand with a name that invites customers to step into a role," says Boadle. Rooted in London, where Cockney Rhyming Slang originated during the Victorian era, 'Arthur Sleep' whimsically translates to 'Half-Asleep'. This alludes to the nocturnal escapades of Arthur Sleep and the dreamlike experience of crafting your perfect pair of shoes, as if in a dream.

After rapper A$AP Rocky came to hear of the shoes, and purchased a pair, word started to spread, and Arthur Sleep got its brand into Selfridges. Today, it makes shoes for international celebrities such as Prince William, Colin Firth, Robert De Niro and Martin Freeman. It has won many awards, such as the best emerging brand from Pitti Uomo. Now, it is able to produce over one hundred pairs per week, and not just slippers but sliders, loafers, desert boots, espadrilles, trainers and even accessories and textiles for superyachts and private jets.

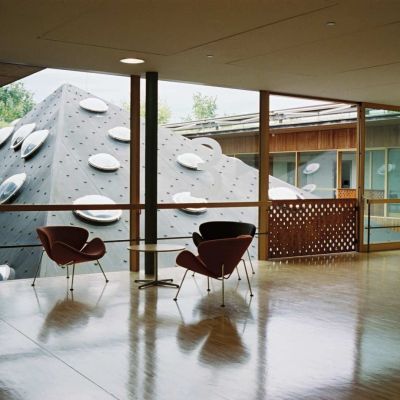

The Arthur Sleep flagship store is special. In fact, it is a historic milestone, as London's first shoe factory in over a century. “It’s the return of shoemaking to London; it’s something we’re very proud of,” says Azam. The store is a feast for the eyes, centred around a curved bar made from hand-cut polished green onyx, sourced from Iran and waterjet cut in southern Spain. The walls are covered in a muted Venetian limewash executed by conceptual artist Samuele Sinibaldi, an angular triple suspension lamp by Joe Armitage lights up vibrant contemporary art, a revolving exhibition. Here is where customers come for their initial measurements; a lasting trunk is used to take an impression of their feet, alongside the use of state-of-the-art 3D scanning technology. The whole process takes just three minutes.

But it’s underneath the floor where the real magic happens. I walk into a 64-square-metre micro-factory buzzing with industry. Here, five permanent skilled cordwainers (the traditional British term for shoemakers) beaver away on beautiful shoes, some of whom have been brought out of retirement as there are simply so few skilled shoemakers, says Boadle.

He adds: “No one was offering the sort of shoes we were doing and there was no real luxury shoe manufacturing being done in the UK. So, it was very much a mission from day one.”

“We wanted the customisation to be at the heart of it; it’s much more pleasurable and fun,” says Azam. And the word customisation barely goes far enough. Patrons can submit their own materials to make into shoes. To date, the team has produced shoes from customers’ old yacht sails, a Royal Mint coin bag, cherished suits that have finally exceeded their capacity for economic repair, damaged ski apparel, offcuts of material used to retrim a 1952 Jaguar XK120 and even a parachute that saw service in the Second World War.

Customers can select upper material, sole type and colour and specify personal monogram or motif. More than 140,000 colourway permutations, including materials for the shoe’s upper such as Italian suedes, Scottish leathers, British velvets and even vibrant kilim tapestries, individually sourced from around the world.

The cohort of international patrons who love its shoes rave about their creativity and exquisite quality, the speed of its bespoke manufacturing model, which offers same-day turnaround (order at breakfast and collect your shoes at lunchtime).

But Arthur Sleep also stands for sustainability, its principles of hyper-proximity bringing the entire manufacturing process closer to its customers, reducing waste and carbon expenditure through logistics and supply chains, eliminating landfill waste by controlling stock levels, and safeguarding traditional skills that might otherwise be lost.

“Shoemaking is one of the world’s most polluting industries, so it was imperative for us to move the needle. These matters are of urgent concern to today’s younger luxury consumer,” says Boadle. He points out that over 24 billion pairs of shoes are now produced each year, many sent straight to landfill. Over production, overconsumption and returns due to issues of fit are the focus of their research and development.

As a self-funded enterprise, Arthur Sleep is now embarking on its first capital raise, aiming to finalise the blueprint necessary for expanding its unique micro-factory model into international markets. Boadle and Azam would love to see the brand on iconic shopping streets such as Fifth Avenue in New York, Gangnam in Seoul, Ginza in Tokyo, The Design District in Miami and Orchard Road in Singapore.

Azam says: “When we first came up with this idea, everyone thought we were insane. But to us it was simple: how can we make a business we would want to be customers of?”

This article originally appeared in Billionaire's Impact Issue. To subscribe, click here.